Pulsed Laser Deposition (PLD)

AdNaFilm's Pulsed Laser Deposition (PLD) systems are adept at depositing a wide array of materials with monolayer precision. The entire deposition process is managed by an industrial computer, ensuring full automation for efficiency and accuracy. Operators have the ability to set crucial process parameters, which can be monitored and adjusted in real time, providing greater control over the deposition process. These PLD systems are primarily utilized in the fabrication of quantum devices, showcasing their advanced capabilities in cutting-edge technology applications.

Categories

Menu

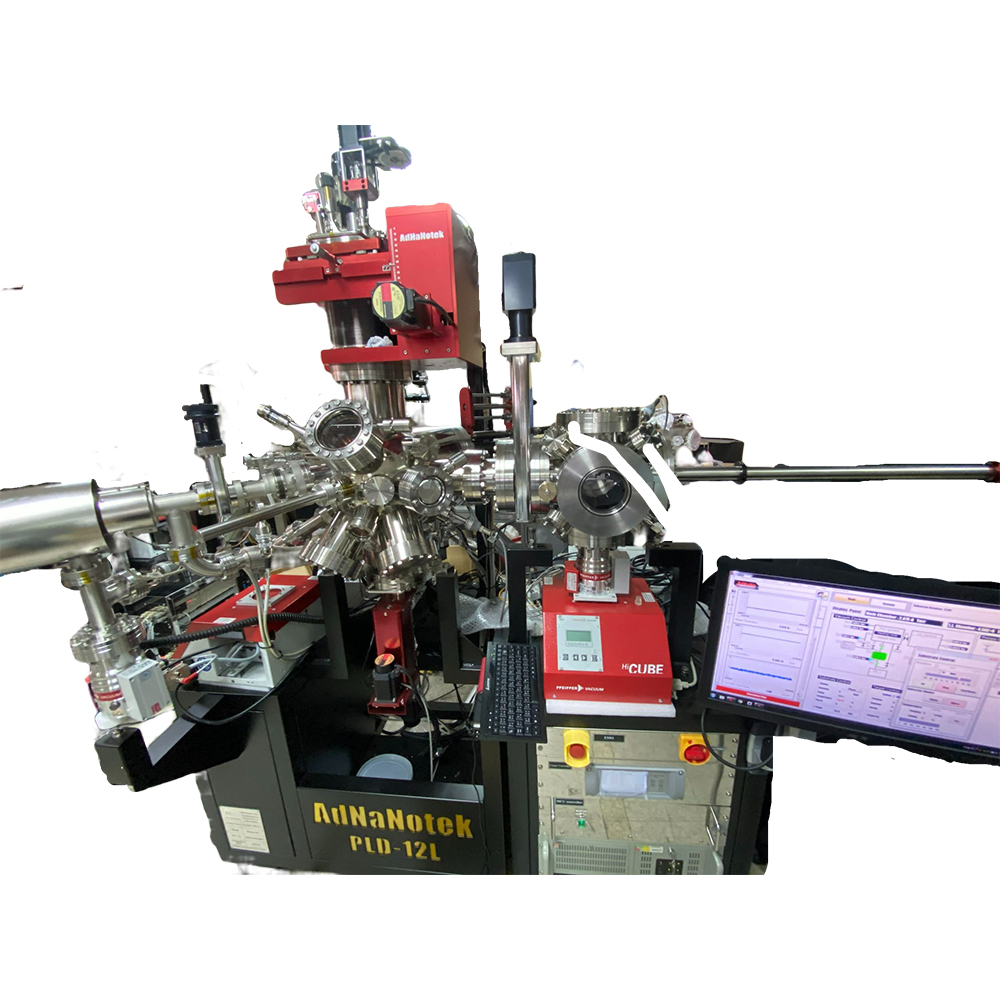

PLD - 12L

( High End )

Pulsed Laser Deposition (PLD)

PLD - 18L

(Very High End)

Pulsed Laser Deposition (PLD)

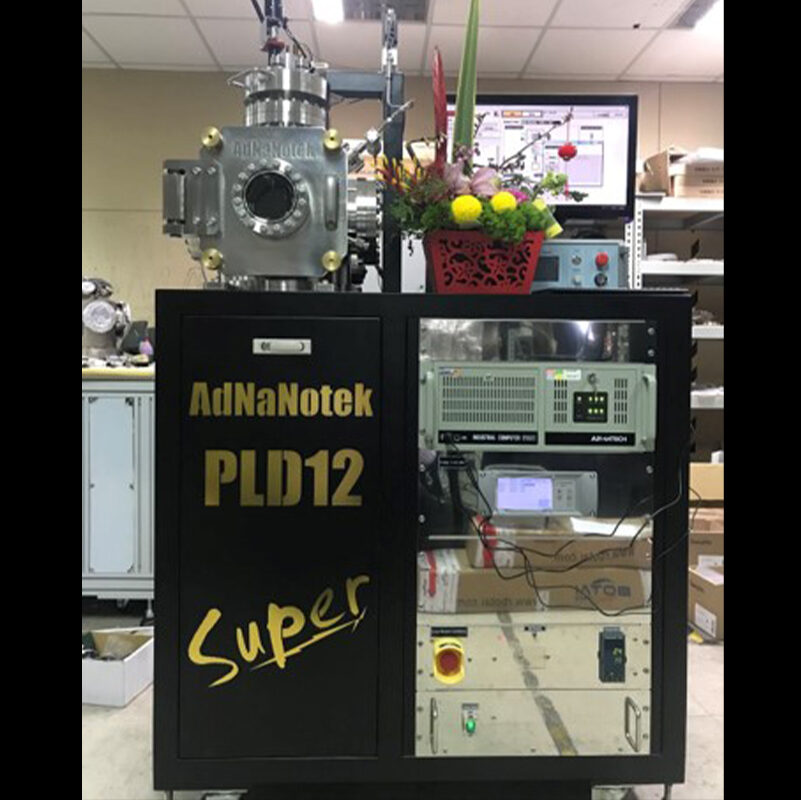

PLD - Super

(Single Chamber)

Pulsed Laser Deposition (PLD)

This integrated Linear transfer system comprises a PLD unit and an Ultra-High Vacuum (UHV) sputtering system. Samples can be seamlessly transferred between these two chambers using a magnetic arm.

The system operates under completely Ultra-High Vacuum (UHV) conditions, offering easy access to substrates.

The sputtering module is equipped with up to 6 cathodes, and it includes a laser heater capable of reaching temperatures up to 1000 degrees Celsius.

The PLD system can be easily upgraded to a Laser Molecular Beam Epitaxy (MBE) setup with the addition of a high-pressure Reflection High-Energy Electron Diffraction (RHEED) system from any RHEED supplier.

The system operates under completely Ultra-High Vacuum (UHV) conditions, offering easy access to substrates.

The sputtering module is equipped with up to 6 cathodes, and it includes a laser heater capable of reaching temperatures up to 1000 degrees Celsius.

The PLD system can be easily upgraded to a Laser Molecular Beam Epitaxy (MBE) setup with the addition of a high-pressure Reflection High-Energy Electron Diffraction (RHEED) system from any RHEED supplier.

Advantages

- Can work in reactive gas environment (e.g. oxygen- or nitrogen-rich environment)

- Versatile method (any material)

- Congruent evaporation

- High deposition rates

- Clean process

- Plume at high energy

- Broad range of gas pressures Φ

- Very slow growth rate

- Any material possible deposition

- Multi material mixing ratio

- Super conductor material, Quantum

Laser Heating Manipulator

AdNaFilm's Laser Heating System is designed as an ideal solution for heating samples in oxygen- and nitrogen-rich atmospheres, while also being compatible with Ultra-High Vacuum (UHV) environments.

AdNaFilm's Laser Heater is engineered to heat substrates with a well-focused beam, ensuring that only the targeted area is heated, thereby providing precise thermal control.

The mechanism of AdNaNoTek's Laser Heater, positioned at a small distance from the plate, maintains a relatively low temperature. This design minimizes outgassing from nearby surfaces, thereby preserving the integrity and purity of the experimental environment.

Moreover, the system's design ensures that its support tube remains cool, even after extended periods of operation, maintaining its low temperature even after 10 hours of continuous use.

AdNaFilm's Laser Heater is engineered to heat substrates with a well-focused beam, ensuring that only the targeted area is heated, thereby providing precise thermal control.

The mechanism of AdNaNoTek's Laser Heater, positioned at a small distance from the plate, maintains a relatively low temperature. This design minimizes outgassing from nearby surfaces, thereby preserving the integrity and purity of the experimental environment.

Moreover, the system's design ensures that its support tube remains cool, even after extended periods of operation, maintaining its low temperature even after 10 hours of continuous use.

AdNaFilm RHEED Screen Set

This RHEED (Reflection High-Energy Electron Diffraction) screen features a shielded protection mechanism. It is designed to block the primary electron beam, preventing potential damage to the phosphorus screen from the strong electron beam. In high-pressure conditions, the electron beam can sometimes become diffused, resulting in a fuzzy appearance.

To address this, our screen is thoughtfully designed to be capable of extending close to the sample or being positioned far from the substrate, enhancing its adaptability and effectiveness in various experimental setups.

To address this, our screen is thoughtfully designed to be capable of extending close to the sample or being positioned far from the substrate, enhancing its adaptability and effectiveness in various experimental setups.

** Target Replacement Under Vacuum

IIn conventional Pulsed Laser Deposition (PLD) systems, replacing the target material necessitates venting the system to the air, which can adversely affect the process parameters and the cleanliness of the system environment.

However, AdNaFilm's PLD system innovatively allows for target replacement under Ultra-High Vacuum (UHV) conditions. This advancement ensures the maintenance of the system's cleanliness and the consistency of process parameters, significantly enhancing the reliability and quality of the deposition process.

However, AdNaFilm's PLD system innovatively allows for target replacement under Ultra-High Vacuum (UHV) conditions. This advancement ensures the maintenance of the system's cleanliness and the consistency of process parameters, significantly enhancing the reliability and quality of the deposition process.

Pulsed Laser Deposition System PLD / Laser MBE

Pulse Laser Scanning in X and Y high speed scan large target laser rastering scan

Seeking to deposit large-sized wafers with exceptional uniformity? Here's the solution!

Equipped with a high-speed scanning system, AdNaFilm's PLD-18L evolves into an industrial-grade Pulsed Laser Deposition tool. It has the capability to deposit on large-sized wafers, accommodating sizes up to 8 inches. This feature not only enables the efficient usage of valuable target materials but also ensures excellent uniformity across the wafer. With PLD-18L, customers can achieve high-quality depositions on large substrates, optimizing both material usage and deposition consistency.

Equipped with a high-speed scanning system, AdNaFilm's PLD-18L evolves into an industrial-grade Pulsed Laser Deposition tool. It has the capability to deposit on large-sized wafers, accommodating sizes up to 8 inches. This feature not only enables the efficient usage of valuable target materials but also ensures excellent uniformity across the wafer. With PLD-18L, customers can achieve high-quality depositions on large substrates, optimizing both material usage and deposition consistency.

Pulsed Laser Deposition (also known as Laser MBE or PLD) is a versatile technique renowned for depositing thin films of exceptional quality and repeatability. This specialized system features an innovative planetary target holder that can accommodate up to 6(9) targets.

This allows the target manipulator to revolve and rotate. The unique target manipulator in this system is designed to both revolve and rotate. This dual action is key: the revolving motion enables the selection of different sample targets, while the rotation, in tandem with the sweep mechanism, enhances the efficiency of target material usage for thin film deposition.

Additionally, the PLD system incorporates a mask system that facilitates the creation of unique deposition patterns on the thin film, further expanding its application range. The target's position is also adjustable vertically, optimizing the distance between the target and the substrate for better deposition results. Moreover, it's engineered for in-vacuum target exchange, which enhances convenience and maintains system integrity.

Flexibility is a hallmark of this PLD system. It can be customized to meet various research needs: it can integrate a multi-functional coating tool extension, compatible with a diverse array of deposition components such as effusion cells, magnetron sputtering sources, and e-beam evaporators. Alternatively, it can be designed with a minimal footprint and compact structure, offering mobility and ease of repositioning, making it ideal for environments where space is at a premium or equipment portability is necessary.

This allows the target manipulator to revolve and rotate. The unique target manipulator in this system is designed to both revolve and rotate. This dual action is key: the revolving motion enables the selection of different sample targets, while the rotation, in tandem with the sweep mechanism, enhances the efficiency of target material usage for thin film deposition.

Additionally, the PLD system incorporates a mask system that facilitates the creation of unique deposition patterns on the thin film, further expanding its application range. The target's position is also adjustable vertically, optimizing the distance between the target and the substrate for better deposition results. Moreover, it's engineered for in-vacuum target exchange, which enhances convenience and maintains system integrity.

Flexibility is a hallmark of this PLD system. It can be customized to meet various research needs: it can integrate a multi-functional coating tool extension, compatible with a diverse array of deposition components such as effusion cells, magnetron sputtering sources, and e-beam evaporators. Alternatively, it can be designed with a minimal footprint and compact structure, offering mobility and ease of repositioning, making it ideal for environments where space is at a premium or equipment portability is necessary.

The PLD (Pulsed Laser Deposition) system, also known as Laser MBE (Molecular Beam Epitaxy), is equipped with a highly sophisticated laser heating manipulator. This feature is particularly effective for providing localized heating, ideal for operations in oxygen-rich or various atmospheric conditions. It has the capability to heat the substrate up to 1200°C at pressures of E-3 torr and below. This targeted heating approach ensures that adjacent components remain at a lower temperature, significantly reducing the risk of substrate contamination due to out-gassing.

Moreover, the process's precision and stability are further enhanced through automation, made possible by the FBBEAR control software. This software offers comprehensive data logging and precise parameter tuning, simplifying the operation process and ensuring reliable experimental repeatability. The user-friendly interface of the FBBEAR control software is a testament to its design, which prioritizes ease of use while maintaining high-quality results.

The versatility of the PLD system is evident in its wide range of applications. It is highly effective for the deposition of thin layers of various materials, including heterostructure metal oxides like Fe/SrTiO3, Nb/SrTiO3, BiFeO3, high-temperature superconducting materials, silicon oxides, high k oxides, metal nitrides, and ferroelectric materials.

This wide material compatibility makes the PLD system an invaluable tool for researchers and engineers working on cutting-edge material science and engineering projects, particularly those focusing on advanced electronic and photonic devices.

Moreover, the process's precision and stability are further enhanced through automation, made possible by the FBBEAR control software. This software offers comprehensive data logging and precise parameter tuning, simplifying the operation process and ensuring reliable experimental repeatability. The user-friendly interface of the FBBEAR control software is a testament to its design, which prioritizes ease of use while maintaining high-quality results.

The versatility of the PLD system is evident in its wide range of applications. It is highly effective for the deposition of thin layers of various materials, including heterostructure metal oxides like Fe/SrTiO3, Nb/SrTiO3, BiFeO3, high-temperature superconducting materials, silicon oxides, high k oxides, metal nitrides, and ferroelectric materials.

This wide material compatibility makes the PLD system an invaluable tool for researchers and engineers working on cutting-edge material science and engineering projects, particularly those focusing on advanced electronic and photonic devices.

In Pulsed-Laser Deposition (PLD), a high-power pulsed laser beam is precisely focused onto the surface of a target material. When the laser pulse hits the target, its energy is rapidly absorbed, leading to a series of energetic transformations. Initially, the energy from the laser is converted into electronic excitation. Subsequently, this energy is transformed into a combination of thermal, chemical, and mechanical energy.

This series of transformations results in the rapid evaporation or ablation of the target material. The intense energy from the laser pulse causes the material at the surface of the target to vaporize instantly, creating a luminous plasma plume. This plasma plume is a highly energetic cloud of ablated target material.

As the plasma plume expands into the surrounding vacuum environment, the ablated materials within it begin to cool and condense. This condensation process leads to the formation of a thin-layer film on the surface of the substrate.

The substrate is strategically positioned to capture this material, resulting in the deposition of a thin film composed of the target material. This method is highly efficient for creating thin films of various materials with precision and uniformity, making PLD a vital technique in material science and nanotechnology applications.

This series of transformations results in the rapid evaporation or ablation of the target material. The intense energy from the laser pulse causes the material at the surface of the target to vaporize instantly, creating a luminous plasma plume. This plasma plume is a highly energetic cloud of ablated target material.

As the plasma plume expands into the surrounding vacuum environment, the ablated materials within it begin to cool and condense. This condensation process leads to the formation of a thin-layer film on the surface of the substrate.

The substrate is strategically positioned to capture this material, resulting in the deposition of a thin film composed of the target material. This method is highly efficient for creating thin films of various materials with precision and uniformity, making PLD a vital technique in material science and nanotechnology applications.

To achieve a monolayer coating in PLD, it is essential to maintain ultra-high vacuum (UHV) conditions and exercise precise control over the parameters governing thin-film deposition.

AdNaFilm's PLD System, equipped with its proprietary system control software, is specifically engineered to meet the aforementioned criteria.

Additionally, AdNaFilm's PLD System comes equipped with Reflective High Energy Electron Diffraction (RHEED) capabilities and accompanying monitoring software for RHEED analysis.

The RHEED system offers real-time monitoring and analysis of the epitaxial growth process by: a) quantifying the growth of individual atomic layers, and b) discerning the growth mechanism, such as epitaxial growth, step flow growth, or three-dimensional island growth.

This technique enables the growth of high-quality thin films and superlattices composed of perovskite-structured materials with atomic layer precision.

The RHEED system offers real-time monitoring and analysis of the epitaxial growth process by: a) quantifying the growth of individual atomic layers, and b) discerning the growth mechanism, such as epitaxial growth, step flow growth, or three-dimensional island growth.

This technique enables the growth of high-quality thin films and superlattices composed of perovskite-structured materials with atomic layer precision.